In the below image, the first pin from the left is the wiper pin. The pinouts of Bourns potentiometer is a bit confusing compared with the standard potentiometer pinouts. In this project, Bourns potentiometer is used. The difference is that the resolution will be less with generic potentiometer because of which the increment or decrement of the current source will not be smooth. The 10 Turn pot is the best for this purpose, but other generic potentiometers also worked just fine. The 5th component in the part list, 50k 10 turn potentiometer is from the Bourns. The JRC4558D Op-Amp is used for this project, but other op-amps will also work. The 8th pin is the positive supply source and the 4th pin is the GND. Any channel can be used for this project. The Pin 1, Pin 2, Pin 3 are used for a single op-amp and Pin 5, 6, 7 used for the other channel. The op-amp used here (JRC4558) follows the same pin diagram as used in other types of the op-amps. Other equivalent transistors are BC556, BC327, 2N3906 etc. From the left to right the pins are Emitter, Base, and Collector. BC557 is the identical pair of NPN BC547. This is one of the most common three pin PNP transistors.

In the below image, The PNP transistor, BC557 pin out is shown. Let’s take a look at the important components used in this project. This circuit can be used as a dummy sensor to emulate programs or for debugging. In this project, we will create a basic current loop tester using few components which allows us to manually adjust current from 4ma to 20mA by turning a potentiometer. It also checks the transmitter output current.

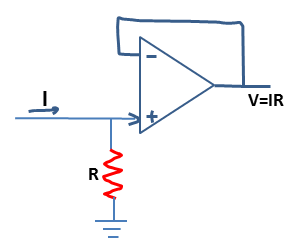

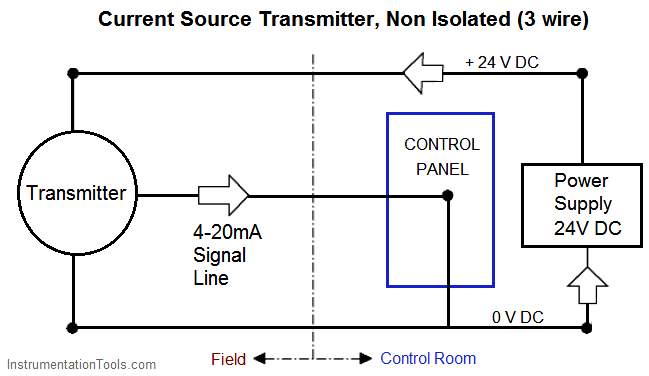

#4 20ma to 0 10v converter circuit diagram verification#

In current loop testing, it uses a verification process that checks breakage in the communication line. In industries, calibration of the sensor is a routine process, and to calibrate the system and also for troubleshooting error results, current loop testing is performed. Also since the signal is transmitted as current it can be sent to long distance without worrying about voltage drop due to wire resistance or about noise immunity. This is because of the situation in which when the output is zero or 4mA, it can still power the device. The sensor outputs the current through twisted pair wires allowing both power and data to flow through only 2 wires. If the sensor output anything less than 4mA or more than 20mA it can assumed as a fault condition. This variable current sensor follows 4-20mA protocol, meaning the sensor will output 4mA when the measured values is 0 and will output 20mA when the measured value is maximum. These analog voltage sensors are coupled with Voltage to current converters to convert the analog voltage into analog current to become a variable current sensor. Many of us should be familiar with sensors that outputs variable voltage like LDR, MQ gas sensor, Flex sensor etc. And Analog sensors could communicate through variable current or variable voltage. Digital sensors communicates with 0’s and 1’s following protocols like USART, I2C, SPI etc. In an industrial environment, the commonly used type of sensors is the Analog Sensor and Digital sensors. Sensors are an integral part of any measurement system as they help in converting the real world parameters into electronic signals that could be understood by machines.

0 kommentar(er)

0 kommentar(er)